As you manage your bustling commercial kitchen, it’s crucial to keep in mind the significance of obtaining and maintaining a Gas Safety Certificate. This document isn’t just another piece of paperwork; it’s a vital safeguard, verifying that all your gas appliances meet stringent safety standards. Remember, it’s not only about staying compliant with legal requirements; it’s about ensuring the safety of everyone in your kitchen—from your staff to your clients. What’s often overlooked, however, are the pitfalls that can occur if this aspect is neglected. Let’s explore what could happen if standards slip and how you can prevent such scenarios. Let’s understand Gas Safety Certificate Essentials for Commercial Kitchens.

Importance of Gas Safety Certificates

Ensuring the integrity of your gas appliances through regular inspections is crucial. In commercial kitchens, where the demand and usage of gas are significantly high, maintaining gas safety isn’t just advisable; it’s imperative.

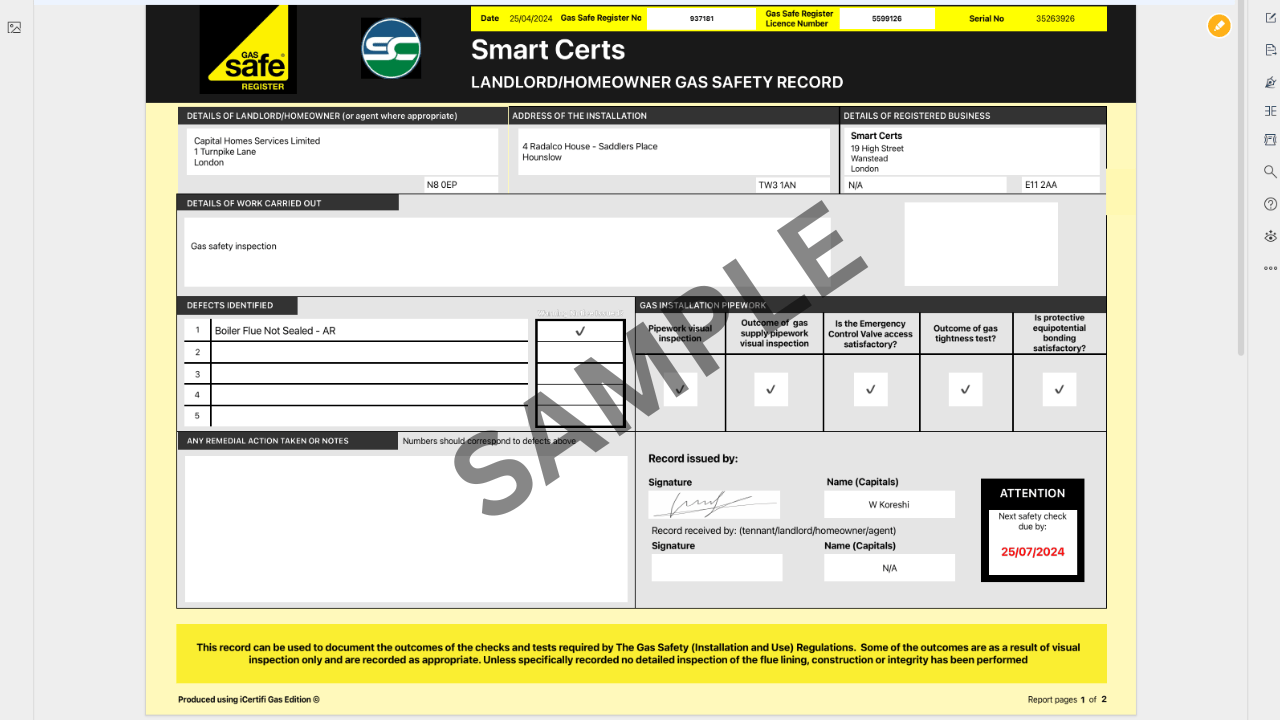

Gas safety certificates serve as formal validations that your kitchen’s gas systems and appliances meet stringent safety standards. These documents aren’t mere formalities—they are comprehensive records resulting from detailed assessments performed by certified engineers.

They examine the installation, maintenance, and operational condition of your gas equipment, ensuring they function within the set safety parameters. Possession of up-to-date gas safety certificates demonstrates your commitment to safety and compliance, significantly mitigating risks of gas leaks or catastrophic failures that could jeopardize both safety and business operations.

Legal Requirements for Compliance

As you focus on maintaining strict adherence to safety standards, it’s equally important to understand the legal requirements associated with obtaining and maintaining a gas safety certificate.

Under the current gas regulations, your commercial kitchen must undergo annual compliance audits to ensure all installations and equipment meet the stringent criteria set forth by national safety authorities.

These audits assess the integrity and functionality of gas pipelines, appliances, and emergency controls, forming the backbone of your certificate’s validity.

Failure to comply not only risks severe legal penalties but also endangers the safety of your staff and patrons.

Therefore, you must stay informed and vigilant, always aligning your operations with the latest regulatory mandates to sustain compliance and ensure uninterrupted kitchen functionality.

Steps to Obtain a Certificate

To secure a gas safety certificate, you must first schedule an inspection with a certified engineer authorized by the national safety authority.

Initiate the application process by submitting a detailed request through the official platform, specifying your commercial kitchen’s location, the type and age of gas equipment, and your availability for the inspection.

The certification timeline can vary, typically ranging from two to four weeks, depending on the complexity of your setup and the engineer’s schedule.

Ensure all your gas systems are accessible and in good working condition to facilitate a smooth review.

Post-inspection, the engineer will provide you with a detailed report. If compliant, your certificate will be issued; otherwise, an inspection might be necessary.

Plan accordingly to align with these timelines.

Common Gas Safety Violations

Understanding common gas safety violations can prevent costly fines and dangerous situations in your commercial kitchen. You must focus on precision in maintaining equipment and rigorously adhering to safety protocols. Regular safety audits and effective gas detection systems are vital for identifying and mitigating risks.

| Violation Type | Consequences |

|---|---|

| Inadequate Ventilation | The build-up of harmful gases, fire risks |

| Faulty Gas Detection Systems | Undetected leaks, potential explosions |

| Poor Maintenance | Equipment failures, safety hazards |

| Non-compliance with Codes | Legal penalties, operational shutdown |

| Neglected Safety Audits | Overlooked hazards, escalated dangers |

Ensure you’re consistently reviewing and updating your practices and systems. Mastery of these aspects is not just about compliance but ensuring the safety and operational efficiency of your kitchen.

Renewing Your Gas Safety Certificate

Renewing your Gas Safety Certificate is a proactive measure to ensure ongoing compliance and safety in your commercial kitchen.

The certificate renewal process isn’t just a regulatory formality; it’s a critical audit of your gas systems and appliances, ensuring they meet strict safety standards. Typically, renewal frequency mandates an annual assessment, but this can vary depending on your equipment’s age and usage intensity.

To initiate the renewal, schedule an inspection with a certified gas safety engineer who will assess all gas connections, appliances, and ventilation systems.

Post-evaluation, any identified issues must be rectified promptly to maintain certification. Staying ahead of renewal deadlines prevents lapses in compliance, thereby safeguarding your operations against potential legal and safety ramifications.

Training Staff on Gas Safety

Training your staff on gas safety is an essential step in maintaining a secure environment in any facility that utilizes gas-powered equipment. Implementing an in-depth gas safety training program elevates staff awareness and fosters a culture of safety.

Begin by educating your team on the properties of gas, potential hazards, and the importance of proper handling. Technical sessions should include the operation of gas appliances, the identification of leaks, and immediate response strategies.

Ensure each team member comprehends the seriousness of gas safety through rigorous assessment techniques. Regularly update training materials to reflect the latest safety standards and technological advancements.

Inspecting Your Gas Appliances

Regular inspection of your gas appliances is crucial to ensuring their safe and efficient operation. You must establish rigorous maintenance schedules that prioritize systematic checks to maintain optimal appliance efficiency.

This involves assessing the physical condition and functional performance of each unit, from ranges and ovens to grills and fryers. Look for signs of wear, such as corrosion or unusual noises, which might indicate a need for repair or adjustment.

Testing the appliance controls and safety features should be part of your routine to guarantee they respond correctly under normal operating conditions.

Handling Gas Leaks and Emergencies

Detecting and addressing gas leaks promptly is crucial for maintaining safety in environments utilizing gas appliances. You must be adept in both gas leak detection and emergency response to mitigate risks effectively.

Initially, familiarize yourself with the smell of gas—often described as a rotten egg odor—to recognize leaks swiftly. Install high-quality gas detectors that alert you to the presence of gas even before it’s perceptible by smell.

In the event of a leak, shut off the gas supply immediately and evacuate the area. Contact emergency services without delay, and don’t attempt to rectify the issue yourself.

Ventilate the space if possible, and wait for professional help. Remember, handling gas emergencies requires precision, quick decision-making, and adherence to safety protocols.

Benefits of Regular Gas Maintenance

Maintaining your gas appliances with routine checks can significantly enhance their efficiency and longevity. By scheduling regular maintenance, you’re not only ensuring operational efficacy but also maximizing cost savings over time.

This proactive approach prevents the frequent breakdowns that lead to expensive repairs and potential business disruptions. Moreover, consistent upkeep extends equipment longevity, safeguarding your investment in high-quality commercial kitchen infrastructure.

It’s crucial to recognize that well-maintained gas appliances consume less fuel, thus reducing overall energy costs. Additionally, regular inspections help in adhering to safety standards, minimizing the risk of hazardous incidents.

In essence, committing to systematic maintenance is indispensable for optimizing performance, achieving substantial cost efficiencies, and ensuring the long-term viability of your gas appliances.

Conclusion

You must prioritize obtaining and renewing your Gas Safety Certificate to ensure your commercial kitchen remains compliant and safe. Adhere strictly to the legal requirements and schedule annual inspections by certified engineers. Regular training for your staff on handling gas emergencies and maintaining appliances is crucial. This proactive approach not only prevents potential violations but also fortifies your operational integrity, ultimately protecting your business from legal issues and fostering trust among stakeholders.