In the landscape of workplace safety, Portable Appliance Testing (PAT) stands as a critical preventive measure, yet determining which electrical appliances require testing can be a daunting task. From everyday office essentials like computers and printers to complex industrial machinery, the range of devices subject to PAT is vast. As safety regulations continually evolve and the line between ‘necessary’ and ‘excessive’ testing becomes less defined, businesses must stay ahead to ensure both compliance and safety. With the ever-present risk of electrical malfunctions, a pressing question arises: Are we truly doing enough to protect our workplaces from potential hazards? Read on as we dive into the specifics of PAT testing and what it means for your business. Let’s understand Which Electrical Appliances Require PAT Testing?

Understanding the Importance of PAT Testing

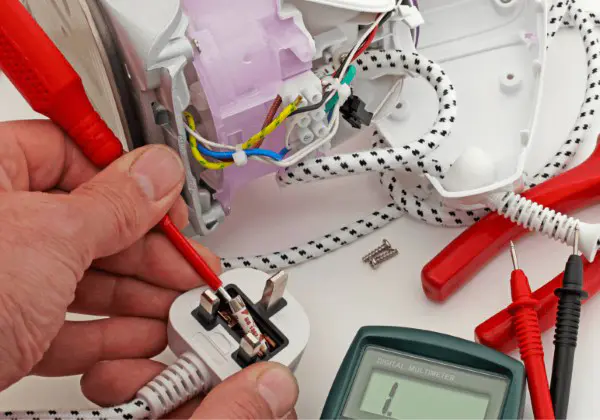

Understanding the importance of PAT (Portable Appliance Testing) is crucial for ensuring the safety and efficiency of electrical appliances in both domestic and commercial settings. This thorough testing method helps in identifying potential electrical faults that could lead to safety hazards or operational inefficiencies.

PAT testing benefits both users and businesses by ensuring that all appliances adhere to rigorous safety standards, thus mitigating the risk of electrical accidents which could lead to severe injuries or fires. One key aspect of PAT testing is its role in compliance with legal and safety regulations. Organizations are mandated to ensure that their electrical installations and appliances are safe for use, and failure to comply can result in severe legal penalties and damage to reputation.

Through systematic examination and testing, PAT contributes to the extended lifespan of appliances by detecting early signs of wear and tear or improper handling that may not be obvious to the untrained eye. By addressing these issues promptly, businesses can avoid costly repairs or replacements and minimize downtime due to equipment failure.

In essence, the practice of PAT testing exemplifies proactive safety compliance and operational assurance, making it an indispensable component of modern electrical safety management strategies.

Electrical Equipment That Must Undergo PAT Testing

Identifying which electrical equipment requires PAT testing is a critical step in maintaining workplace safety and compliance with health and safety regulations. Both home appliances and industrial equipment fall under the scope of items that must be periodically assessed to ensure they operate safely and effectively.

For home appliances, consider the frequent use of devices such as microwaves, toasters, and electric kettles. These items, due to their regular interaction with high temperatures and electrical currents, are prone to wear and potential electrical faults, making them prime candidates for PAT testing.

Similarly, larger appliances like washing machines and dryers also require inspection, primarily due to their complex mechanisms and constant use.

Moving to industrial equipment, the stakes are higher due to the larger scale and increased power usage. Items such as manufacturing machinery, power tools, and large-scale heating systems must undergo rigorous testing.

These pieces of equipment not only ensure the continuity of business operations but are critical in preventing workplace accidents caused by equipment failures.

Essential Office Devices Needing Regular PAT Inspection

Regular PAT inspections are imperative for ensuring the safety and functionality of essential office devices such as computers, printers, and photocopiers. Ensuring these devices are regularly checked not only enhances office safety but also plays a critical role in extending the appliance lifespan, thus influencing overall productivity and operational costs.

Office environments typically house a myriad of electrical devices that are integral to daily operations. This includes external hard drives, shredders, and fax machines, all of which require diligent maintenance. The regularity of PAT testing for these devices depends significantly on their usage and environmental conditions. For instance, devices exposed to higher levels of dust or mechanical stress may necessitate more frequent evaluations.

Technicians conducting PAT inspections focus on several key aspects: wiring integrity, insulation effectiveness, and operational functionality. This comprehensive analysis ensures that each device adheres to current safety standards, thus mitigating any potential hazards such as electrical shorts or overheating, which could lead to office fires or equipment failure.

How to Determine If Your Appliances Need PAT Testing

Determining the necessity for Portable Appliance Testing (PAT) in your office equipment involves assessing several critical factors. The age of the appliance and the frequency of its usage are paramount in this evaluation.

Older appliances may have deteriorated insulation or worn-out wiring that can pose serious safety risks. Therefore, the age of an appliance should be considered as a potential indicator of the need for more frequent testing.

Furthermore, how often a device is used can significantly influence its likelihood of failure. Equipment that is used daily is subjected to more wear and tear compared to those used less frequently, increasing the risk of electrical faults.

It is crucial to create a detailed inventory of all electrical appliances in the workplace, documenting their age and usage patterns. This record will serve as a foundational tool in determining the priority and frequency of PAT tests.

Technical managers should also consider the manufacturer’s guidelines and any past maintenance records to assess the residual risks associated with each appliance.

How Frequently Should You PAT Test Electrical Equipment?

Understanding the appropriate frequency for Portable Appliance Testing (PAT) is integral to maintaining the safety and operational reliability of electrical equipment in the workplace. The PAT testing frequency can vary significantly depending on several factors. These include the type of appliance, its use, and the environment in which it is operated.

Ensuring adherence to recommended testing intervals is crucial for compliance with safety regulations.

Here are key guidelines for determining the frequency of PAT tests:

- Risk Assessment: Conduct a thorough risk assessment to determine how frequently each type of appliance should be tested. Heavily used or more mobile equipment typically requires more frequent testing.

- Environment: Appliances used in harsh environments (e.g., construction sites, industrial areas) should be tested more frequently than those in less demanding settings (e.g., office spaces).

- Manufacturer’s Guidelines: Always consider the manufacturer’s recommendations on testing intervals as part of compliance with safety standards.

Regular PAT testing not only ensures compliance with health and safety regulations but also enhances the longevity and efficiency of electrical equipment.

Why Hire Certified PAT Testing Experts in London?

Hiring certified PAT testing experts in London is a critical decision for any business aiming to ensure the safety and efficiency of its electrical appliances. Certified technicians bring a level of expertise and meticulousness necessary for thorough inspection and testing, crucial for maintaining safety compliance.

These professionals are equipped with the latest diagnostic tools and have undergone rigorous training to identify potential electrical hazards before they lead to accidents or costly failures.

Utilizing certified experts ensures adherence to the latest Health and Safety Executive (HSE) guidelines and local regulations, which is paramount for legal compliance and protecting against liability. Moreover, these specialists can provide detailed reports and documentation that support an organization’s commitment to safety standards, which is essential during audits and inspections.

The technical proficiency of certified PAT testers allows for precise fault detection and assessment of electrical equipment’s operational integrity. This proactive maintenance not only enhances the longevity and performance of the appliances but also fortifies the safety protocols of the business environment.

Therefore, investing in certified PAT testing services in London is indispensable for businesses prioritizing robustness in their operational safety and regulatory compliance.

Conclusion

In conclusion, Portable Appliance Testing is an indispensable safety protocol that encompasses a wide range of electrical appliances, from domestic to industrial and office equipment. Regular PAT testing ensures compliance with safety regulations, helps in the identification of potential electrical faults, and significantly reduces the risk of accidents. Organizations and individuals must engage certified professionals to conduct these inspections, thereby safeguarding property and lives against electrical hazards.