In the realm of fire safety, the classification of fires into categories A, B, C, D, and K is not merely academic but a practical framework essential for effective response strategies. Each class denotes a specific type of fuel involved, requiring distinct approaches for suppression and safety measures. For instance, the techniques employed to extinguish a Class A fire, which involves ordinary combustibles, differ markedly from those required for a Class C fire, where electrical equipment presents additional hazards.

Understanding these distinctions is crucial for anyone responsible for fire safety, as it influences the selection of appropriate fire extinguishers and preventive practices. However, the nuances of these classifications reveal deeper implications for both safety protocols and emergency response. Let’s understand What Are the 5 Different Classes of Fire and How to Safely Extinguish Each One.

The 5 Different Classes of Fires

Understanding the five different classes of fires is crucial for implementing effective fire safety measures and selecting the appropriate firefighting techniques. Each class corresponds to the types of materials involved, which in turn determines the fire behavior and the strategies for both fire prevention and suppression.

Class B fires involve flammable liquids and gases such as gasoline, propane, and butane. These fires require methods that smother flames or remove oxygen to extinguish the fire, emphasizing the importance of proper storage and handling of volatile substances to mitigate risks.

Class C fires are electrical and often occur in environments dense with electronic equipment. These fires necessitate non-conductive extinguishing solutions to prevent further electrical hazards and damages, highlighting the necessity for regular maintenance and safety inspections.

Class D fires involve combustible metals like magnesium and titanium. The unique and vigorous reactions of metals to typical extinguishing methods, such as water, demand specialized agents like dry powders. Understanding the specific characteristics of these materials is essential for safe and effective firefighting.

Class K fires are kitchen fires from grease, oils, and fats. They are prone to rapid spread and require specific agents to smother flames efficiently. Regular training and appropriate fire safety measures in food service areas are critical to prevent and manage these high-risk fires effectively.

Class A Fires: Ordinary Combustibles

Class A fires, encompassing ordinary combustibles such as wood, paper, and fabric, represent the most prevalent fire class across diverse environments, from residential settings to industrial locations. These fires can ignite and spread rapidly, fueled by materials commonly found in numerous settings, underscoring the necessity for robust fire prevention strategies and practices.

To effectively manage these risks, it is imperative to implement stringent safe storage measures. Materials prone to ignition, such as loose paper or textiles, should be stored in non-combustible containers and kept away from heat sources.

Regular inspection and maintenance of storage areas are crucial to eliminate potential ignition sources and reduce fuel loads.

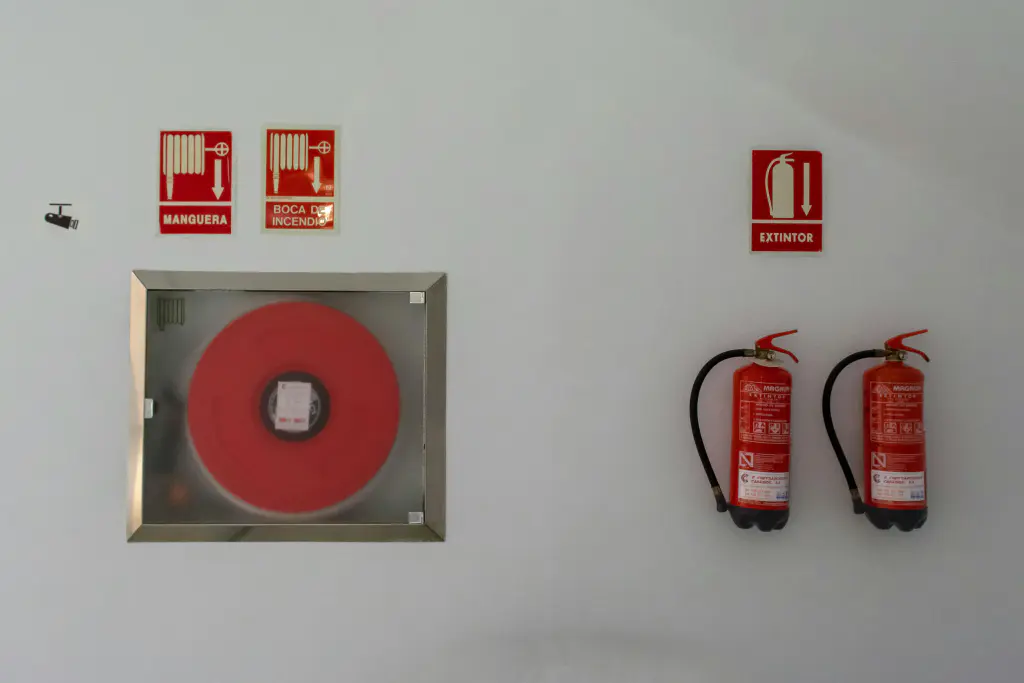

Moreover, clear pathways and properly marked exits are essential to ensure a quick evacuation in the event of a fire, thereby mitigating potential injuries and property damage. Installation of smoke detectors and fire extinguishers tailored for Class A materials can provide early detection and initial firefighting capability, crucial in preventing the escalation of fire.

Educational programs on fire safety should also be established, emphasizing the importance of fire prevention techniques in the everyday handling and storage of combustible materials. Such proactive measures are fundamental in safeguarding both lives and property against Class A fires.

Class B Fires: Flammable Liquids & Gases

While the management of Class A fires centers on ordinary combustibles, Class B fires present unique challenges due to their involvement with flammable liquids and gases such as gasoline, propane, and butane. These substances, often stored under high pressure or in large volumes, can escalate a fire scenario rapidly.

The volatile nature of these materials necessitates specific strategies in flammable storage and gas handling to prevent escalation and facilitate effective suppression.

In extinguishing Class B fires, the primary objective is to interrupt the chemical chain reaction of the fire, typically through smothering. Fire suppression agents such as foam, carbon dioxide, or dry chemicals are preferred because they create a barrier between the fuel and the oxygen surrounding it, effectively suffocating the fire.

Unlike water, which can spread flammable liquids, these agents prevent the fire’s spread by isolating the fuel.

Given the high risks associated with flammable liquids and gases, stringent regulations govern their storage and handling. Safety protocols include proper container labeling, regular inspections, and the use of containment systems designed to control leaks and spills.

Training for emergency response teams also emphasizes quick and decisive action to manage these volatile elements before a manageable incident escalates into a catastrophic event.

Class C Fires: Electrical Fires

Navigating the complexities of electrical fires requires a specialized approach due to their origin in failed or faulty electrical equipment, such as wiring, appliances, and industrial machinery.

Understanding the unique challenges posed by these types of fires is critical for effective fire prevention and safety management. The following key points outline the essentials of dealing with Class C fires:

- Identification and Risk Assessment:

- Recognize environments prone to electrical hazards, including commercial buildings and manufacturing facilities.

- Regularly assess these areas to identify potential risks and implement corrective measures.

- Safety Protocols and Equipment:

- Utilize appropriate fire extinguishing agents that are non-conductive, such as carbon dioxide (CO2) or dry chemical extinguishers, to avoid electrical conductivity.

- Ensure that all personnel are trained on the specific protocols for electrical fire emergencies.

- Maintenance and Prevention:

- Conduct periodic inspections and maintenance of electrical systems to prevent overheating and wear that could lead to fires.

- Upgrade outdated or damaged electrical components systematically to reduce risk factors.

- Emergency Response Planning:

- Develop and regularly update emergency response plans that include specific procedures for electrical fires.

- Conduct drills to ensure all employees understand their roles during an electrical fire incident, enhancing the overall safety and readiness of the organization.

Class D Fires: Combustible Metals

Handling fires that involve combustible metals, such as magnesium, titanium, and sodium, presents unique challenges that require specialized knowledge and equipment. These metals can ignite and burn at high temperatures, and traditional firefighting methods can be ineffective or even dangerous. Understanding the properties and risks associated with each metal is crucial for effective fire suppression and ensuring metal fire safety.

| Metal | Characteristics |

|---|---|

| Magnesium | Burns at approximately 3,100°C |

| Titanium | Requires an inert atmosphere to extinguish |

| Sodium | Reacts explosively with water |

| Potassium | Similar reactive nature as sodium |

Extinguishing agents for Class D fires must be carefully selected to avoid reactions that could exacerbate the fire. Common agents include dry powder formulations specifically designed for metal fires, such as sodium chloride or graphite-based powders. These agents work by smothering the fire and isolating the metal from oxygen, effectively cutting off the fuel supply.

Professionals dealing with such fires must be thoroughly trained in the use of these extinguishing agents and equipped with appropriate personal protective gear. Regular drills and updated safety protocols are essential to prepare for potential incidents involving combustible metals.

Class K Fires: Grease & Cooking Fires

In the realm of fire safety, Class K fires, which involve cooking materials such as grease, oils, and fats, represent a significant hazard in both residential and commercial kitchens.

These fires are uniquely challenging due to the high temperatures and the volatile nature of the substances involved. Understanding the properties and appropriate responses to Class K fires is critical for effective fire safety management and prevention of severe damage and injuries.

Here are four key aspects of Class K fires:

- High Ignition Temperatures: Cooking oils and fats can ignite at temperatures much higher than most other combustible materials.

Once ignited, the high energy content of grease and oils fuels the fire rapidly.

- Extinguishing Methods: Traditional water-based extinguishers are ineffective and can exacerbate grease fires.

Instead, Class K-specific extinguishers use wet chemical agents that cool the fire and react to form a soap-like substance that seals the surface and prevents re-ignition.

- Rapid Spread: Due to its liquid nature, grease can spread over surfaces quickly, expanding the area of a fire more rapidly than solid combustibles.

This trait demands swift and precise action to control the spread.

- Detection and Suppression Systems: Modern kitchens, especially in commercial settings, are equipped with advanced fire suppression systems designed explicitly for grease safety and cooking hazards.

These systems are crucial in early detection and automatic suppression of fires, reducing risk and damage.

Prevention and Safety Tips

To effectively mitigate the risk of fire incidents, it is imperative to adopt comprehensive prevention and safety measures tailored to the specific characteristics and hazards associated with each class of fire. Conducting thorough risk assessments forms the cornerstone of any robust fire safety strategy.

For Class A fires involving common combustibles, ensuring clear and maintained escape routes and regular removal of waste materials can drastically reduce potential fuel sources. In environments prone to Class B fires, the focus should be on proper storage and handling protocols for flammable liquids and gases to prevent leaks and spills.

Class C fires necessitate regular inspections and maintenance of electrical equipment and installations to prevent malfunctions or overheating. Where metallic substances are involved, as with Class D fires, workers should be trained in the specific risks associated with reactive metals and the correct use of Class D-specific extinguishing agents.

Finally, for Class K fires typically found in kitchens, installing appropriate fire suppression systems and conducting regular cleanliness inspections will help prevent grease buildup, a common ignition source.

Implementing these targeted prevention techniques will significantly enhance fire safety and readiness, aligned with the specific risks presented by each class of fire.

Extinguishing Techniques Explained

Understanding effective extinguishing techniques is paramount for addressing different classes of fires, each demanding a unique approach to suppression. Mastery of these techniques is critical for safety professionals and emergency responders to efficiently and safely manage fire incidents.

Below is a concise exploration of extinguishing methods tailored to the nature of each fire class:

- Class A Fires: Utilize water or monoammonium phosphate-based extinguishers. The suppression agents work by cooling the burning material and interrupting the chemical reaction of the fire triangle.

- Class B Fires: Employ foam, carbon dioxide, or dry chemical extinguishers. These agents smother the fire by creating a barrier between the fuel and the oxygen, effectively cutting off the fire’s air supply and halting the combustion process.

- Class C Fires: Use non-conductive chemicals such as dry chemicals or carbon dioxide extinguishers. Since these fires involve electrical equipment, the suppression agents are designed to extinguish the fire without conducting electricity.

- Class D Fires: Apply dry powder extinguishers specific to the metal involved, such as sodium chloride or copper-based powders. These agents work by forming a crust that isolates the metal from oxygen, suppressing the fire without causing a reaction.

Each method involves specific suppression agents designed to target the unique properties of the fire’s fuel source, ensuring effective and safe extinguishing practices.

Conclusion

In conclusion, understanding the different classes of fires—A, B, C, D, and K—is crucial for selecting the appropriate firefighting strategies and extinguishing agents. Effective fire prevention and safety management depend on a thorough knowledge of these classifications, each characterized by specific fuels and corresponding extinguishing techniques. Awareness and preparedness are key in mitigating risks associated with fires, ensuring the safety of individuals and the protection of property through tailored responses to various fire scenarios.