Asbestos, a once ubiquitous material praised for its heat resistance and insulating properties, has left a troubling legacy in a wide array of building materials and consumer products. From the insulation in homes to the brakes in cars, the presence of asbestos in older materials raises significant health concerns, primarily due to the risk of mesothelioma and other asbestos-related diseases.

Identifying these materials is not only crucial for health but also for legal and environmental reasons. However, the list of asbestos-containing materials extends beyond the obvious, encompassing products one might not initially consider. What could these less obvious products be, and what implications does their discovery have for public health and safety? Let’s uncover Which Materials Contain Asbestos?

Common Asbestos-Containing Products

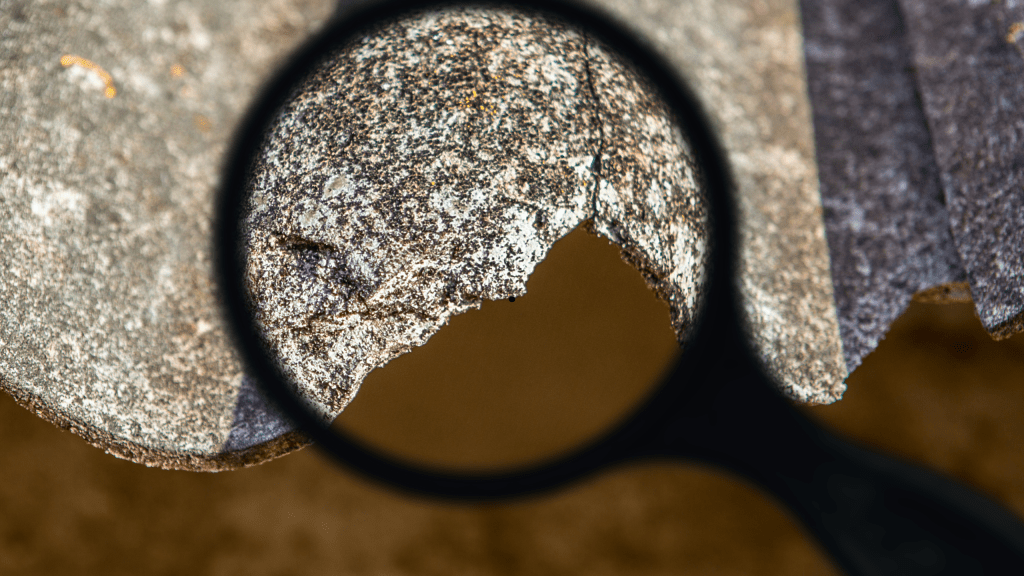

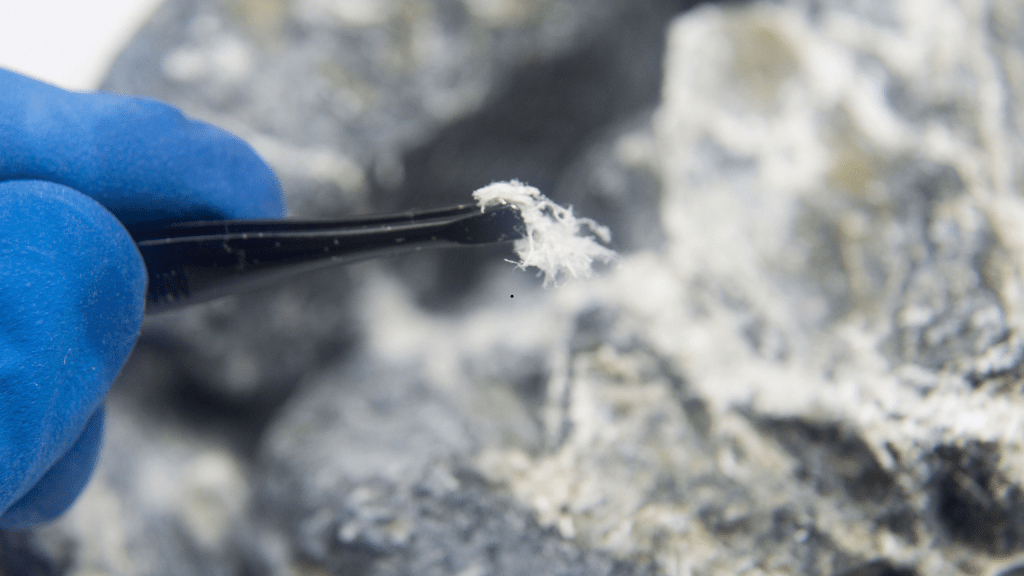

Asbestos, a naturally occurring fibrous mineral, was extensively utilized in various building materials due to its durability and resistance to heat and chemicals. Its identification and the corresponding health risk assessments are critical components of asbestos management, particularly given the severe health risks associated with exposure.

Precision in identifying asbestos in existing structures necessitates a blend of visual inspections and meticulous sampling, followed by polarized light microscopy (PLM) or transmission electron microscopy (TEM). These methods allow for the accurate detection and quantification of asbestos fibers, which is essential for risk evaluation.

Health risk assessments involve systematic procedures to evaluate the potential risk posed by the presence of asbestos in building materials. This includes assessing the condition of the material, the probability of fiber release, and the potential for human exposure.

These assessments must be carried out by competent professionals who can interpret the results of asbestos tests and anticipate the behavior of asbestos-containing materials under various conditions. Ultimately, this detailed analysis helps in deciding the necessity for removal or containment measures, directly impacting the safety protocols to mitigate exposure risks.

This rigorous approach ensures that management and remediation strategies are both effective and compliant with regulatory standards, safeguarding public health.

Building Materials With Asbestos

Commonly found in numerous construction components, asbestos has been historically favored for its fire-resistant and insulating properties. Building materials such as insulation, roofing shingles, ceiling tiles, and floor tiles often contain asbestos due to these advantageous characteristics. The presence of asbestos in these materials poses significant health risks, necessitating strict adherence to asbestos regulations and safety protocols to minimize exposure.

Asbestos regulations mandate that all construction and demolition activities involving ACMs) must be carried out with the utmost care. These regulations require proper identification, handling, and disposal of ACMs to ensure both worker and public safety. The Control of Asbestos Regulations 2012, for instance, outlines specific guidelines for managing ACMs in buildings, including the necessity of an asbestos management plan and regular risk assessments.

Asbestos safety is paramount, and adherence to these regulations is monitored by the Health and Safety Executive (HSE), which enforces compliance and investigates potential breaches. Employers and property owners must ensure that all personnel involved in construction or maintenance are adequately trained in asbestos awareness and equipped with appropriate safety gear to handle or work around ACMs safely.

This rigorous approach helps to mitigate the health risks associated with asbestos exposure, safeguarding both individual and public health.

Asbestos in Consumer Goods

While asbestos is widely recognized for its use in building materials, its presence is not limited to industrial applications alone. Asbestos has also historically been used in various consumer goods, posing significant risks to consumer safety. The pervasive use of asbestos in everyday products was governed by stringent asbestos regulations, which have evolved to limit its application and enhance public health protections.

Protect Your Health Get an Asbestos Survey Today

Consumer products known to have contained asbestos include certain older appliances, automotive parts, and even some household items. These products once utilized asbestos due to its heat-resistant properties, before the health risks were fully understood. Current regulations strictly limit the use of asbestos in consumer goods, but legacy products may still pose risks, emphasizing the importance of awareness and proper risk management.

The table below illustrates common consumer goods that historically contained asbestos, emphasizing the need for vigilance and compliance with safety standards:

| Product Type | Asbestos Use |

|---|---|

| Appliances | Heat-resistant insulation |

| Automotive Parts | Brake pads and clutch linings |

| Household Items | Older ironing board covers |

| Garden Products | Some older pesticides and fertilizers |

Understanding these risks and the history of asbestos in consumer goods underscores the critical need for ongoing education and adherence to safety protocols to prevent exposure.

Asbestos Use in Insulation

It is widely acknowledged that asbestos was extensively used in building insulation due to its excellent thermal resistance and durability. The unique asbestos properties, such as its resistance to heat, fire, electrical and chemical damage, made it an ideal material for insulation in various building structures, from residential homes to commercial buildings and industrial facilities.

This widespread application, however, has led to significant health risks, necessitating strict protocols around insulation safety. Asbestos-containing insulation products were predominantly used to wrap pipes, boilers, and ductwork, and in attic insulation as loose-fill, batts, and blankets.

While these applications provided effective thermal control, the fibers, if disturbed or deteriorating, pose severe inhalation risks, leading to diseases such as mesothelioma, asbestosis, and lung cancer.

Insulation safety now demands comprehensive risk assessments and stringent management plans to control exposure. The removal or disturbance of asbestos insulation requires specialized containment procedures and should only be performed by licensed professionals equipped with appropriate personal protective equipment.

This ensures both environmental safety and health protection for workers and residents, aligning with legal frameworks designed to mitigate asbestos-related risks. Effective asbestos management in insulation is critical to preventing long-term health effects and ensuring safety in environments where asbestos was historically utilized.

Asbestos in Automotive Parts

Asbestos has been historically utilized in various automotive parts, primarily for its heat resistance and durability. Particularly, asbestos in brake pads and asbestos in gaskets were widespread due to their ability to withstand high temperatures and prevent wear under friction. The inclusion of asbestos provided essential performance characteristics critical in automotive safety and efficiency. However, the health risks associated with asbestos exposure led to a significant reconsideration of its use in automotive components.

The table below highlights the emotional and factual aspects of asbestos use in automotive parts:

| Aspect | Impact |

|---|---|

| Heat Resistance | Ensured safety in high-temperature environments |

| Durability | Extended lifespan of automotive components |

| Health Risks | This led to serious diseases like mesothelioma |

| Regulatory Changes | Initiated shifts toward safer alternatives |

| Current Use | Limited due to stringent safety standards |

This transition from asbestos-containing components like brake pads and gaskets to safer alternatives marks a critical evolution in automotive manufacturing. It reflects a broader commitment to health and safety, despite the technical benefits that asbestos once provided. The automotive industry’s response to the asbestos crisis underscores the priority of human health over traditional manufacturing practices, a move supported by both regulatory frameworks and public health advocacy.

Asbestos in Older Appliances

Older appliances, such as heaters, ovens, and hairdryers, often incorporated asbestos due to its superior insulation properties. Asbestos, recognized for its heat resistance and electrical insulation capabilities, was a staple in the manufacturing of older appliances to enhance safety against fire hazards and overheating.

However, as awareness of asbestos-related health risks grew, the use of asbestos in appliances was phased out. Nevertheless, many older appliances still in use or improperly stored may pose significant health risks.

For those dealing with older appliances, it is essential to prioritize asbestos safety and ensure proper appliance disposal. Below are critical considerations:

- Identification: Before any maintenance or disposal of older appliances, it is crucial to identify potential asbestos-containing components. Typically, these include insulation around heating elements and wiring.

- Professional Handling: Engage professionals trained in asbestos handling for any repair, removal, or disposal tasks. This reduces the risk of asbestos fiber release, which can occur if the materials are disturbed.

- Safe Disposal: Follow local regulations on asbestos waste handling and disposal. This often involves sealing the asbestos-containing materials in secure containers and labeling them appropriately before transportation to designated disposal facilities.

Understanding and implementing these steps ensure compliance with asbestos safety regulations and minimize health risks associated with asbestos exposure during appliance disposal.

Asbestos Presence in Textiles

Several textiles historically utilized asbestos due to its heat-resistant properties, especially in products that required durability under high temperatures. In the realm of textile manufacturing history, asbestos was often integrated into fabrics used in various industrial applications where heat and fire resistance were paramount. This included but was not limited to, fireproof curtains, firefighters’ gear, and insulation materials for machinery and pipes.

Asbestos detection techniques have evolved significantly, enhancing our ability to identify and quantify asbestos fibers in textile samples. These advancements underscore the critical need for rigorous safety protocols in industries handling historical or suspected asbestos-containing textiles.

| Aspect | Detail |

|---|---|

| Historical Uses | Firefighters’ gear, insulation materials |

| Detection Techniques | Advanced microscopy, spectroscopy |

| Safety Protocols | Regular assessments, specialized handling |

The transition from the use of asbestos in textiles has been driven by the increased awareness of its health risks and the development of safer alternative materials. However, the legacy of its use remains a concern, necessitating continued vigilance and expertise in asbestos management within textile-related industries. This historical context not only informs current safety practices but also guides future innovations in textile manufacturing.

Conclusion

In conclusion, asbestos has historically been utilized in a wide array of products due to its advantageous properties such as durability and heat resistance. This includes building materials, consumer goods, automotive parts, and even textiles. The recognition of the health hazards associated with asbestos fibers, particularly when these materials are disturbed, underscores the importance of awareness and proper management to prevent exposure. Continued vigilance is essential in dealing with existing asbestos-containing materials to safeguard public health.